Heavy-Duty Synthetic Grease Provides Extreme Protection

5100 is the Aerosol version of "Pyroshield 5182 Grease"

Pyroshield Syn Open Gear Grease is a heavy-duty synthetic lubricant developed for large unshrouded open gears in the mining, mineral processing and cement industries, and for other severe service applications that require a lubricant with superior wear protection, exceptional load-carrying ability, outstanding tackiness and ease of application at various temperatures. It also works well for applications in which gears experience high point-of-contact temperatures of 327ºC (620ºF) and above.

A product of advanced lubricant technology providing boundary lubrication, unmatched performance and versatility, Pyroshield Syn Open Gear Grease is formulated with high-viscosity 100 percent synthetic base oil, a non-melting thickening system and LE's proprietary heat stable additives. It contains a synergistic mix of Almasol®, LE's exclusive wear-reducing additive, and a unique combination of extreme pressure additives.

Pyroshield®, Almasol® and Duolec® are registered trademarks of Lubrication Engineers, Inc.

Lubrication Engineers operates under an ISO 9001 Certified Quality System.

5100 is the Aerosol version of "Pyroshield 5182 Grease"

Pyroshield Syn Open Gear Grease is a heavy-duty synthetic lubricant developed for large unshrouded open gears in the mining, mineral processing and cement industries, and for other severe service applications that require a lubricant with superior wear protection, exceptional load-carrying ability, outstanding tackiness and ease of application at various temperatures. It also works well for applications in which gears experience high point-of-contact temperatures of 327ºC (620ºF) and above.

A product of advanced lubricant technology providing boundary lubrication, unmatched performance and versatility, Pyroshield Syn Open Gear Grease is formulated with high-viscosity 100 percent synthetic base oil, a non-melting thickening system and LE's proprietary heat stable additives. It contains a synergistic mix of Almasol®, LE's exclusive wear-reducing additive, and a unique combination of extreme pressure additives.

Pyroshield®, Almasol® and Duolec® are registered trademarks of Lubrication Engineers, Inc.

Lubrication Engineers operates under an ISO 9001 Certified Quality System.

Unit of Measure

Benefits and Recommendations

Available Container Size |

N/A Single Aerosol |

Buy this LE Product! |

N/A Don't See Pricing? Register Today! |

Beneficial Qualities |

N/A

|

Available Grades |

N/A

LE's proprietary additives are used exclusively in LE lubricants. Pyroshield Syn Open Gear Grease contains Almasol. Almasol® solid wear-reducing additive is able to withstand extremely heavy loads, chemical attack and temperatures up to 1,900ºF (1,038ºC). It is attracted to metal surfaces, forming a microscopic layer but not building on itself or affecting clearances. Almasol minimizes metal-to-metal contact and the resulting friction, heat and wear. |

Proprietary Additive |

N/A

LE's proprietary additives are used exclusively in LE lubricants. Pyroshield Syn Open Gear Grease contains Almasol. Almasol® solid wear-reducing additive is able to withstand extremely heavy loads, chemical attack and temperatures up to 1,900ºF (1,038ºC). It is attracted to metal surfaces, forming a microscopic layer but not building on itself or affecting clearances. Almasol minimizes metal-to-metal contact and the resulting friction, heat and wear. |

LE Modified Timken Test |

N/A

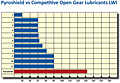

Conclusion The graph clearly shows the outstanding preventive wear performance that Pyroshield Syn Open Gear Grease provides as compared to competitive products. Load Wear Index (LWI) is a measure of lubricant's ability to carry a load and minimize wear. The higher the value, the better the lubricant does in preventing wear.  |

Pyroshield vs Competitive Open Gear Lubricants LWI |

N/A

Conclusion The graph clearly shows the outstanding preventive wear performance that Pyroshield Syn Open Gear Grease provides as compared to competitive products. Load Wear Index (LWI) is a measure of lubricant's ability to carry a load and minimize wear. The higher the value, the better the lubricant does in preventing wear.  |

Recommendations |

N/A

Using Pyroshield 5100 & 5180

|

Typical Applications |

N/A

|

Asset Reliability Solutions |

N/A Reliability Solution Products |

Customer Testimonials |

N/A

5100 City of Moore |

Physical Characteristics - Typical

Thickener Type |

N/A Bentone |

Texture |

N/A Smooth/Tacky |

Color |

N/A Purple |

NLGI Grade as Applied |

N/A 2 |

NLGI Grade in Service |

N/A 2 |

Performance Test Results

Worked 60 Penetration ASTM D217 |

N/A 275 |

Worked 10K Penetration ASTM D217 |

N/A +14 |

Worked 100K Penetration ASTM D217 |

N/A +28 |

Dropping Point ºC(ºF), ASTM D2265 |

N/A Non-melt |

Flash Point ºC (ºF), ASTM D92 |

N/A 224 (435) |

Viscosity @ 100°C, cSt, ASTM D445 |

N/A 690 |

Viscosity @ 40°C, cSt, ASTM D445 |

N/A 26,180 |

Pour Point °C (°F), ASTM D97 |

N/A 3 (37) |

Oxidation drop in psi @ 100 hrs, ASTM D942 |

N/A 3 |

Corrosion Prevention DI H2O, ASTM D1743 |

N/A Pass |

Timken OK Load lbs, ASTM D2509 |

N/A 90 |

Four-Ball EP Weld Point kgf, ASTM D2596 |

N/A 500 |

Four-Ball EP Load Wear Index kgf, ASTM D2596 |

N/A 116 |

Four-Ball Wear @ 75ºC (167ºF), 1,200 rpm, 40 kgf, 60 minutes, mm wear, ASTM D2266 |

N/A 0.71 |

Water Spray-off % Loss, ASTM D4049 |

N/A <2.0 |

Copper Corrosion 24 hrs @ 100ºC, ASTM D4048 |

N/A 1b |